| What's Hot! | Products/ Tools | EFI Tuning | Basic Tuning | Advanced Tuning | Chassis Tuning | Advertise with us |

Why your Car NEEDS A CATCH CAN!

Why every car/truck, especially force induction cars, should be running a catch can

Contributed By: Enginebasics.com

It seems like every company out there now is offering a catch can set-up for a certain car or truck and there is good reason. This article will talk about what a catch can is and why you should be running one. Trust me, READ IT. You’ll learn something you probably didn’t know Mr. Know-it-all!

What is a catch can?

A catch can is a container that is plumbed into the car engine in a manor that will catch oil vapors. These cans are sometimes large and others times not so much. Some of them will have breathers on top, while others will be a closed system. No matter what, a good catch can will have some sort of aerator or separator located inside.

Why do I need a catch can?

While most people understand that a forced induction motor (one that is turbo or supercharged or bottle fed) has pressure many don’t know that N/A motors do as well. As a piston goes up and down in the cylinder it creates pressure areas both in the cylinder and the crankcase as the speed of the piston itself in its return stroke is moving a lot of air. This pressure often gets into the crankcase as some of the cylinder pressure gets past the rings or from the piston travel itself and then moves on into the valve cover. This reduces the ability of the rings and other seals to do their job. In fact, running a small amount of negative pressure actually shows an increase in engine power. Read our article on dry sump systems to find out more information on this. Therefor engine manufactures want to make sure that a small amount of vacuum is always applied to the crankcase and valve covers.

A factory designed crank case pressure system will usually just have a couple of lines that run from the valve covers and crank case over to the intake in some area. They are always pre-throttle body so that they are always seeing vacuum. In forced induction applications the lines are usually run to the intake tube before the turbo or superchargers intake, where they will be subject to vacuum the entire time the engine is running. Some OEM manufacturers have run vent lines to other area’s of the intake pre-throttle body, but you will notice that they install check valves on these lines so that once the car or truck engine makes boost the check valve will close and pressure will not have access to the valve cover or crankcase. Below are examples of the check valves you will need:

These designs of using the engines own vacuum to keep pressure down in the crankcase does have its downside. This vacuum is pulling air out of an area that has oil vapor flying around inside. This causes the air that is pulled in these areas to contain vaporized oil in it. This oil is then sucked into the intake path of the motor where it flows in the general intake path and get’s burned in the motor. So is this a bad thing? Yes and no. It is not bad in the fact that this vacuum we are pulling on the engine is good for it and helping up the efficiency of the seals and rings. Also there is no maintenance for the owner. The oil vapors are burned in the combustion cycle so no harm no foul. So what’s the bad?

The bad part of this is that oil has an extremely low octane level. This vaporized oil will essentially be lowering our octane level in its combustion. Also the oil does not contain the BTU rating of gasoline, ethanol, methanol or whatever we are currently running for fuel, so the air density that it is now being taken up means less air that we can put into the engine for us to match with a good air/fuel mixture and make power. Another negative for those running intercoolers is that when the lines are connected in a way that pulls vacuum pre-turbo, which most OEM manufacturers do, than the oil vapor will coat the inside of the intercooler causing the efficiency to go down as it effects the intercoolers ability to transfer heat out of the intake air. Another negative is that this injected oil causes terrible carbon build up on the intake path wrecking havoc on the valves and piston tops. If you haven’t heard, manufactures are having a terrible time with carbon build up on the new direct injection motors that don’t have any intake port type injection to help clean out the carbon. Walnut blasting is starting to become a regular BIG MONEY maintenance item on cars and trucks now because of this. So to summarize that all up, it causes intercooler efficiency to go down, octane to go down, carbon buildup, and air density to go down. For those paying attention all four of those things make engine power go down. Now why does the oem manufacture do this then and not just have a catch can?

First reason is because of EPA standards. You can’t have oil vapors having access to the atmosphere, so to deal with this they are then ingested and burned. Second reason is because of the convenience. Many owners hate the fact that they have to change the motor oil every 5,000 miles. Can you imagine having a can under the hood that you ask them to empty every now and then? Do you really think they would do it? And if they forgot major damage could occur, so ask yourself what you would do? Yah, I would do the same thing the major manufactures are doing. Plumb it into the intake and take the horsepower and torque loses in efficiency. But what about us enthusiasts who are looking for max power and don’t mind popping the hood and checking things every now and then. For those owners its time to add a catch can set-up to the engine.How does a catch can work?

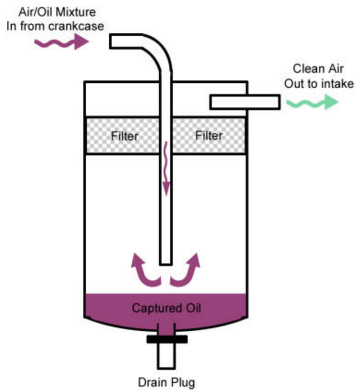

A catch can works by separating the oil out of the air that comes from the crankcase or valve covers and holds that oil inside of itself, not allowing it to continue into the motor or air. Depending on the type of catch can setup you have chosen to go with will depend on how your catch can works. Lets talk about the two major designs

- Atmospherically Vented Catch Can

This type of catch can will have large filters located at the top of the can and be open to the engine bay space. These types of catch cans function based on the ability of them to breathe well and not develop pressure or vacuum inside due to being open to the atmosphere. Because they rely on the natural ventilation of any pressure or vacuum the lines feeding this type of can should be over sized for the application since they are not vacuum assisted. Multiple -10 AN lines should be considered the LEAST one should use for this type of catch can. Crank case pressure has actually been measured to decrease when going from -10 AN lines to -12 AN lines before with this type of set-up. This suggests that when relying on a natural pressure difference to exhaust the crank case pressure you can’t go too big.

- Vacuum assisted Catch Can

With the vacuum assisted catch can, a line is plumbed into the intake path of the engine so that it receives a slight vacuum. This vacuum line helps assist in the evacuation of the crankcase/valve cover pressure. One must be careful to only attach this line to an area of the motor that ALWAYS RECIEVES VACUUM under all conditions or they will have to install a check valve.

This type of catch can set-up has the opportunity to be a lot more efficient than the atmospheric one we spoke of above, but one must then take extra care in installing a well made catch can. One will quickly notice that when searching for a catch can to purchase many will just be an empty can. This is not technically a proper catch can. A proper catch can should have some sort of aerator located inside that helps to separate the oil out of the air. Many catch cans have baffling systems or filters located inside to accomplish this. Vacuum assisted catch cans can get away with running vent lines as small as -6AN (3/8” ) because of the vacuum that is assisting in the removal of pressure from the engine.

Why not have the catch can drain the oil back into the oil pan?

Another thing we should discuss is the set-up of a catch can that has the ability to make the system maintenance free. There actually were some early manufactures that setup catch cans on cars that drained the oil back into the oil pan making it a win win situation for all parties. This type of system was later abandoned because it was found that this oil once aerated would cool inside the catch can causing condensation. This condensation (water) would then drain itself into the pain diluting the engine oil slightly. This is why those with catch can set-ups will notice that the oil they drain out of their catch can is often milky looking do to the amount of contamination in the oil.

What are the steps to set-up a proper catch can?

Start by not purchasing a garbage catch can. There are so many on the market with absolutely ZERO engineering in them, while others have swirl pots, baffles, trap doors, and aerators located inside of them. This is another case where you’re going to get what you pay for.

Example of good catch can design:

I see terrible catch can set-ups all the time where the owner thinks it’s amazing and says things like “I have had that catch can for years and never had to drain it once”. Hey buddy, this is not something you brag about. That’s like bragging about driving your car 50,000 miles and not having to change the motor oil once. If you have a good catch can with an efficient set-up you should catch “some” oil at some point. Now amount is totally different for every set-up, but for those with forced induction, you’re going to collect more. For those that run their cars hard to redline a lot, you’re going to collect more. For those with an old tired motor with worn out seals, you’re going to collect more. I think you get the idea. If you’re not collecting any oil though you either drive like a grandma or have a terrible set-up. Below are some REAL catch cans that should be considered over a lot of the trash that is being sold as proper catch cans:

Once you have a good catch can, a line should be run from each valve cover over to the catch can. From there it depends on the catch can you purchased. If it’s an atmospheric can, than install the filters and you’re all set. If it’s a vacuum assisted catch can than you would now route a line over to a port in front of the throttle body if the car is natural aspirated, or before the turbo or supercharger if you have forced induction.

Setting up the ULTIMATE CATCH CAN set-up for MAXIUMUM EFFICENCY

Ok so you want to know how to set-up a super efficient catch can setup for maximum evacuation and efficiency? Start with a large catch can that has several inlets into baffled areas with filtering elements. Those areas should then drain to an area below while air can pass through to another chamber. In the next chamber you run an outlet to the intake that pulls vacuum. You should have at least 3 inlets to the catch can, one from each valve cover and one from the crankcase. These lines are at least -10AN lines and a larger -12AN line is run to the inlet.

If you are looking to do a catch can set-up that is vented to the atmosphere it was tested on a high revving forced induction four cylinder, that it took at least two -12 AN lines from the valve cover and one -12 AN line from the crank case to a large catch can with two 1.5” K&N breather filters mounted on top to keep pressure down. You really can’t have too much line size and ventilation in the case of a atmospheric set-up. (click for larger image)

Understand that every motor is different based on how it was built with the amount of ring gap the motor is running, how high it revs, the amount of boost pressure it runs, and so on. This article should contain everything you need to know to get a catch can set-up on your car or truck and help you stop the carbon build up that is potentially coating your motor.

If you enjoyed this article let us know. Like and follow us on Facebook and twitter, and be sure to check out the links found at the top of the page to many other articles found here at enginebasics.com. We hope to be your go to website for basic engine tuning and modifying articles as well as general maintenance and tune-ups.

ATTENTION READER:

If you enjoyed the information and article you just read be sure to check out our newly released book with even more exciting photo's and information:How to Turbocharge and Tune your Engine

Want to know more about your particular Make and Model vehicle? All of these vehicles are covered in the tech, maintenance and repair articles found above. Enginebasics is the wiki or wikipedia of car part, repair, how to and tuning information. Let us be the class 101 for your automotive learning.

| Ford | General Motors GM | Pontiac | Jaguar | Land Rover | Nissan |

| Toyota | Honda | Lexus | Acura | Lotus | Scion |

| Infinity | BMW | Mercedes | Mitsubishi | Ferrari | Maserati |

| Lamborghini | Volks Wagen VW | Saab | Audi | Hyundai | Kia |

| Subaru | Mazda | Chevy | Volvo | Caddilac | Dodge |

| Chrylser | Daewoo | Porsche | Mercury | Freightliner | MG |

Individual Models

| Ford Mustang | Mitsubishi Eclipse | Mitsubishi Evo | Subaru WRX / STI | Dodge Viper | Chevrolet Corvette |

| Nissan Skyline | Honda S2000 | Nissan 350z | Toyota Supra | Chevy Camaro | Lotus Elise Exige |

| Honda Civic | VW Golf | Dodge SRT-4 | Eagle Talon | Acura Integra | BMW M3 |

| Nissan 240sx | Porsche 911 | Acura NSX | Honda Accord | Toyota Camry | Toyota MR2 |

| VW R32 | Dodge Truck | Mazda Rx7 | VW Jetta | Sand Buggy | Nissan Sentra |

For the latest Automotive news and stories visit the websites below |

Our feature Build: An AWD V6 Civic